Flushing Rigs

Product Overview

90% of mechanical failure is due to contamination.

Our Flushing Rig range is your essential care and maintenance system. Save on large repair and replacement bills by using our new revolutionary flushing rig range to flush, filtrate and clean contaminants that can build up in your hydraulic systems.

Failure to carry out basic flushing tasks can cause hydraulic system failure resulting in unscheduled, costly downtime and repair or replacement of systems. Our innovative range of flushing rigs are not only suitable for flushing hydraulic systems but can also be utilised for subsea drilling, hydrostatic testing & functioning, testing Christmas Trees, BOP’s and URT’s. Designed with unrivalled knowledge and expertise you can be sure our robust range of flushing rigs can provide you with a solution to suit your specific requirements.

Ensure you are minimising the maintenance of your systems, the risk of irreparable damage and maximise reliability; start maintaining your hydraulic equipment today.

Key Features

-

Hydraulic Oil or Water/Glycol Fluid Options

-

Flow rates up to 150 LPM (33.3 Gallons) per minute as standard

-

Pressures up to 10,000 PSI (700 Bar) as standard

-

Built in filtration system

-

Pump Run Dry prevention feature

-

Integral drip tray to prevent spillages

-

Bespoke designs available

-

Atex/DNV Options available

* Please note that figures about may vary due to the type of hydraulic oil or water/glycol being used. To confirm performance is correct our sales team will require information on the fluid to be used.

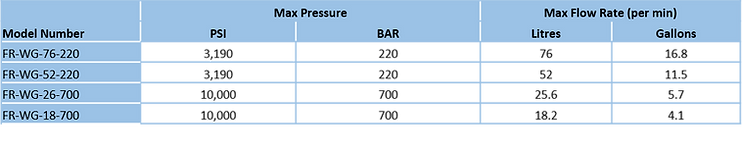

Water/Glycol Range

The list below shows the most popular flushing rigs suitable for water/glycol in our range, however we also offer many other flows and pressures as standard. For any requirements not listed contact our sales department.

* Please note that figures about may vary due to the type of hydraulic oil or water/glycol being used. To confirm performance is correct our sales team will require information on the fluid to be used.